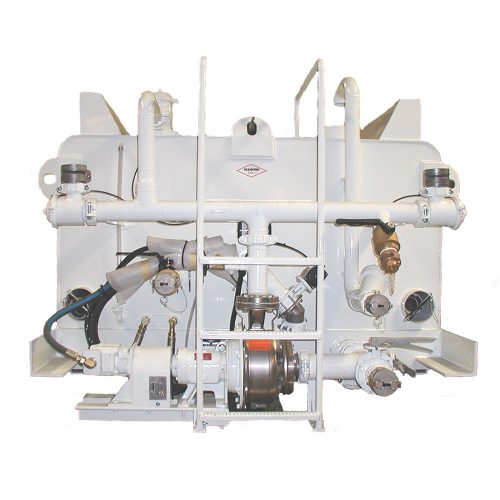

Diamond Bilt Water Trucks are built with a focus on high quality craftsmanship and outstanding performance. Whether you are looking for a hydraulically driven system or a driveline system, stainless steel or black iron, we have a truck for you! Customize the truck to fit your exact needs. We have tanks with capacities ranging from 1,000 to 5,000 gallons and everything from street flushers and fan sprays to hose reels and water cannons. We also fabricate systems for potable water.

Call us today to discuss your next truck.

Reviews

There are no reviews yet.